Filter technology for this industry:

Industry challenges

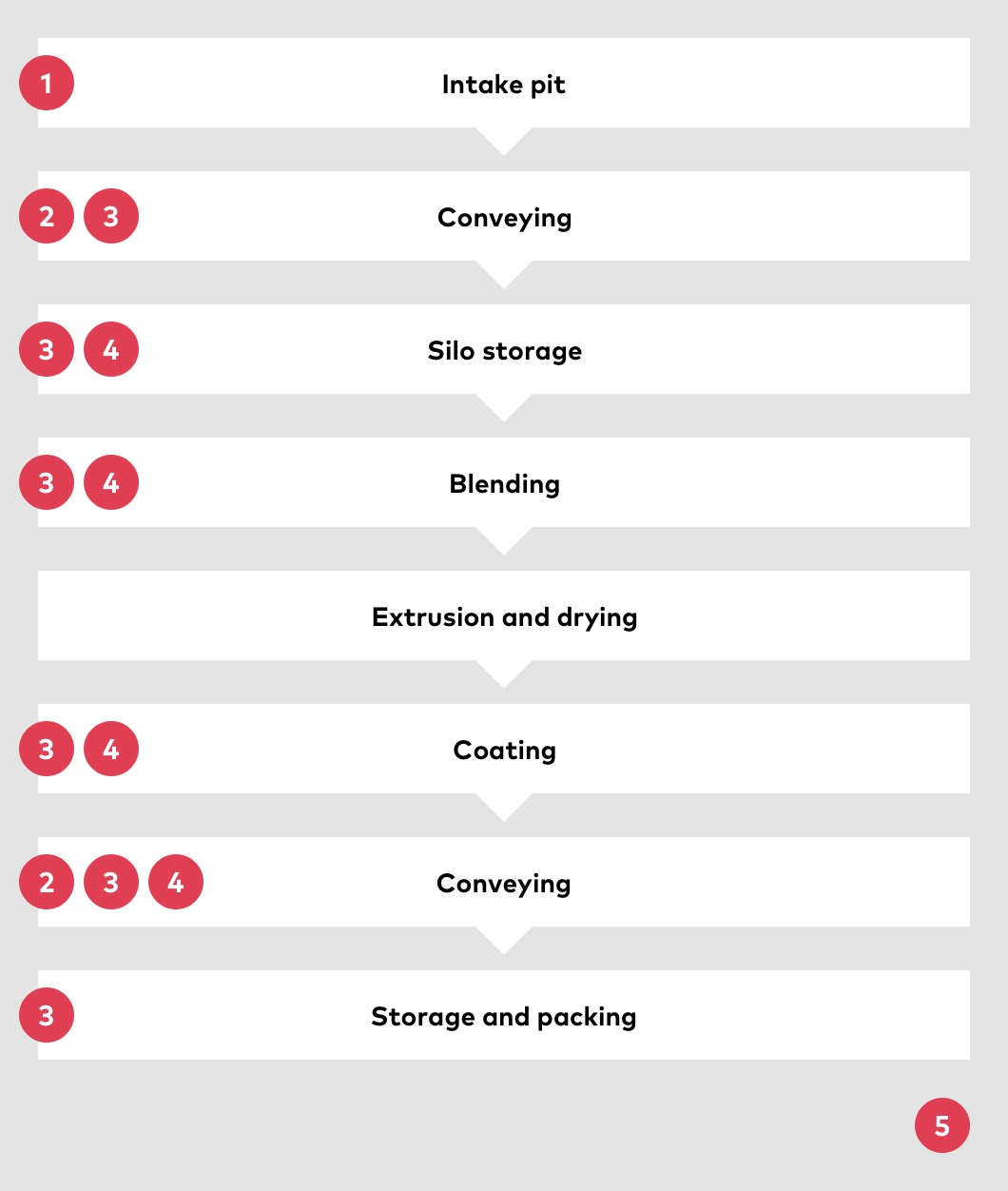

Manufacturing high-quality dry and wet food and food supplements for pisci-culture and pets requires an increasing variety in their composition and production processes.

Our filtration technology is suited to handle the processes involved – grinding, mixing, extruding, drying or cooling. We do this by ensuring secure production areas, optimised processes and optimised product recovery while meeting the necessary quality requirements.

Pet and fish food industry requirements

- Implementation according to ATEX EN 14491 and VDI 3673 directives

- Capacity: from 3. 1 to 435,6 m²

- Pressure shock resistance:from 0,64 to 2 bar

- Reduction of harmful dust to correspond to the values of the TA air

- Efficient tool-free filter change in the pure gas and raw gas area

- Optimal filtration using different filter variants

- Temperature resistant seals

- Manual and automatic setting of cleansing cycles

- Available with water and oil-divergent surfaces

- Dry food for pisci-culture

- Domestic pet food

- Supplement feed for horses

- Animal and meat bone meals

Our approach

Simatek’s filtration solutions are developed to meet the challenges and unique needs of the pet and fish food industry.

Based on our long-standing experience and expertise, we offer solutions that are efficient, environment friendly and ensure optimal results while offering customers good value for money.

Our customers benefit from:

- Improved processes and high productivity

- Assurance of sustained and improved final product quality

- Improved working conditions

- Low operating costs through reduced maintenance costs and minimum downtime

- Optimal use of resources

- Quick return on investment